Jingke Yulong SMT Service

The SMT workshop is newly equipped with 30 fully automatic, high-precision, high-speed SMT production lines, all of which are composed of the world-class YAMAHA company's YSM20 Panasonic NPM-D3 cutting-edge high-speed placement equipment. RAY/Intelligent First Piece Tester.

-

Logistics check

-

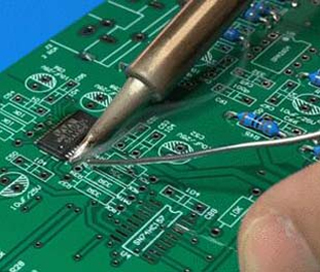

manual welding

-

Solder paste inspection

-

In post-soldering functional test

-

QA full inspection

-

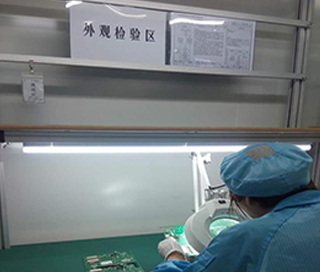

external assessment

-

X-RAY detection <

-

The turntable machine is working at high speed

Production equipment

Processing capacity

Existing 30 SMT production lines, equipped with new imported Fuji XPF, NXT3, automatic solder paste printing machine, ten temperature zone reflow oven, AOI, SPI and other high-end equipment, the SMT production capacity is 31.5 million solder joints / day, especially good at high Precision and high-complexity veneers have actual performance in producing super-complex veneers with 40,000+ solder joints.

| SMT capacity | 5 million solder joints/day |

| SMT production line | Yamaha Turntable 5 lines |

| throw rate | Resistance-capacitance ratio 0.3% |

| IC class without throwing | |

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate |

| Mounted Component Specifications | Pasteable smallest package | 03015 Chip/0.35 Pitch BGA |

| Minimum device accuracy | ±0.04mm | |

| IC type chip accuracy | ±0.03mm | |

| Mounted PCB Specifications | PCB size | 50*50mm - 774*710mm |

| PCB thickness | 0.1-6.5mm |