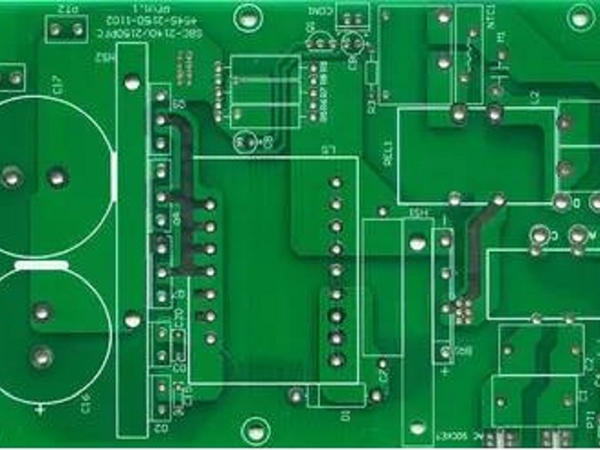

It is often said that the quality of the board can be guaranteed only by choosing an excellent PCB circuit board proofing expert. So when you choose a manufacturer that you think is excellent, how do you judge whether the proofed circuit board is excellent? As a professional PCB proofing expert, Jingke Yulon will share with you today, how can the proofed PCB circuit board make customers satisfied?

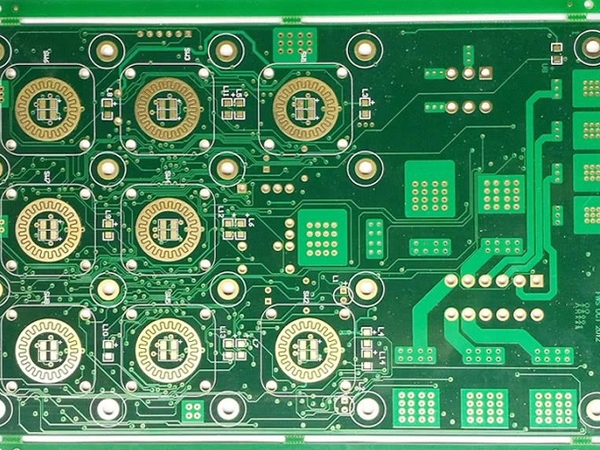

First, the copper skin is not easy to fall off in a high temperature environment;

Second, the line thickness, line spacing and line width of the line meet the design requirements to prevent the line from heating, short circuit and open circuit;

Third, the PCB circuit board has no additional electromagnetic radiation;

Fourth, in the PCB circuit board proofing process, the quality of high temperature, high humidity and other special environments should be taken into consideration;

Fifth, the copper surface is not easy to be oxidized, which affects the installation speed, and it will not take long after oxidation;

Sixth, it should be ensured that the shape of the board is not deformed, so as to avoid dislocation of the screw holes after installation. Nowadays, mechanized installation is adopted, and the hole position of the circuit board and the deformation error of the circuit design should be within the allowable range.

Combining the above six aspects to measure the proofed PCB circuit board, it can be judged whether it can satisfy customers or not. At present, there are thousands of PCB circuit board manufacturers on the market. It is recommended that users keep their eyes open during the selection process, and choose manufacturers based on a certain understanding of PCB circuit boards to prevent being deceived.