At the beginning of electronic products, the devices used were relatively small, the device size was relatively large, and the number of production was relatively small. In the electronic products produced in this period, the various devices were directly connected using wires.

Later, there were more and more devices in electronic products, the size of the devices became smaller and smaller, and the number of products produced increased. Relying on manual wire cutting alone, the welding efficiency is particularly low, and it is also prone to errors, and it is not easy to maintain after errors. So in order to meet the needs of the process, the printed circuit board was born. The birth of circuit boards has greatly improved production efficiency and can be produced using production lines.

In the beginning, the circuit board was a single layer, that is, the entire circuit board had only one layer of copper. Nowadays, many electronic products with simple functions also use single-layer boards, such as power circuit boards, TV air conditioner remote control circuit boards, etc. Later, as the functions of electronic products became more and more complex, and the devices became more and more complex, the single-layer circuit board became a double-layer circuit board. A double-layer circuit board means that there are copper sheets on both sides of the circuit board, and the middle is connected by vias or pads. Now many industrial control circuit boards and instrumentation circuit boards use double-layer circuit boards.

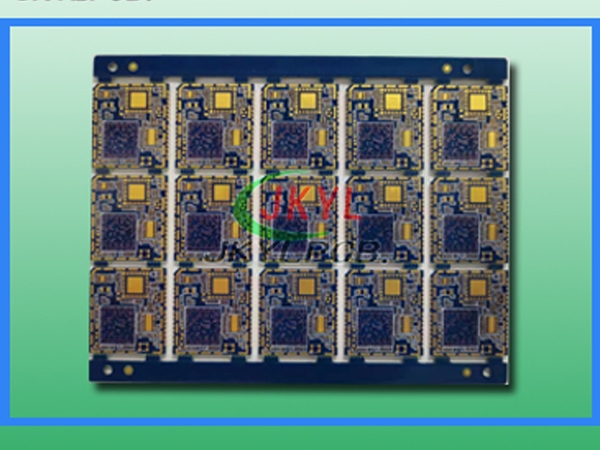

Later, double-layer circuit boards were not enough, so there were 4-layer circuit boards, and two layers of copper sheets were sandwiched between the circuit boards. Now many Bluetooth headsets or smart devices mostly use four-layer boards. Later, there were 6-layer boards, 8-layer boards, and even a dozen-layer boards. These circuit boards are generally used in computer motherboards, memory sticks, and mobile phone motherboards.

Function of PCB circuit board:

1. Provide mechanical support for the fixed assembly of various electronic devices such as integrated circuits, realize wiring between electronic components, and provide required electrical characteristics

2. Provide welding graphics for automatic welding, and provide identification characters and graphics for electronic component insertion, inspection and other links

3. It can realize the functions of automatic insertion or placement of electronic components, automatic welding, etc.

4. Provide the required electrical characteristics, electromagnetic compatibility characteristics and characteristic impedance for high-speed and high-frequency circuits

5. Provide electrical functions for printed boards of passive components

6. Provide an efficient chip carrier for large-scale and ultra-large-scale electronic packaging devices

Classification of PCB circuit boards:

1. According to the number of layers: divided into single-sided, double-sided and multi-layered boards

2. According to soft and hard classification: divided into rigid circuit boards, flexible circuit boards and soft and hard combined boards