How to stick pots on the PCB circuit board efficiently? Many companies are still using manual placement of dome pieces, which is not only inefficient, but also increases the labeling error rate. So if there is a professional automatic dome sticking equipment, can it greatly improve production efficiency and greatly reduce? What about manual labeling error rates?

ATM-250N automatic pot sticking machine is a product independently developed by our company. It has the advantages of high speed (>3600Pcs/H), high precision (±0.1mm), online type and high efficiency. Jingke Yulon has always been with professional and dedicated service concept and service spirit, to achieve real production automation, quality automation, benefit automation for customers, reduce labor costs, improve production efficiency, improve product quality, and win unanimous praise from new and old customers. and long-term support.

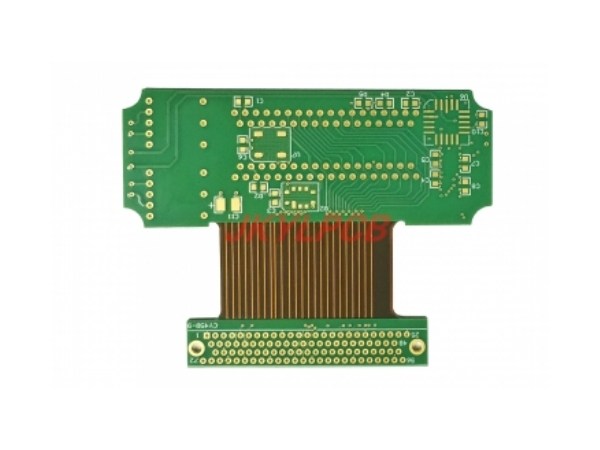

Hardware Description of Automatic Dumpling Piece Equipment

The X/Y motor adopts Japanese imported Sanyo motor, THK linear module, high-precision CCD and supporting software to fully ensure the accuracy and stability of the machine

The high-rigidity integrated steel frame structure ensures the stability of the equipment under long-term high-speed operation

High-resolution camera and stable vision software, stable and efficient positioning algorithm, to ensure stable high-speed production accuracy

The fully automatic pot sticking equipment CCD identifies the standard mark point positioning; the head camera accurately positions the product to ensure the accuracy and stability of the fitting coordinates.

The bottom camera performs contour positioning on the fit material to ensure accurate and stable.