FPC circuit boards can be divided into single-sided, double-sided and multi-layer boards according to the number of circuit layers. Common multi-layer boards are generally 4-layer boards or 6-layer boards, and complex multi-layer boards can reach dozens of layers.

There are three main types of division of circuit boards:

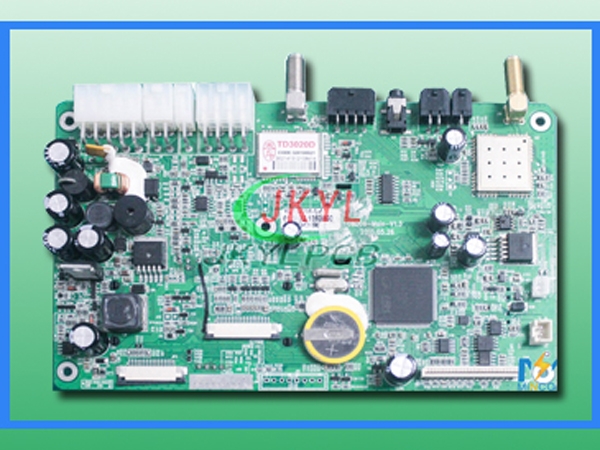

single panel

On the most basic PCB, the single-sided board, the parts are concentrated on one side, and the wires are concentrated on the other side. When there are SMD components, it is the same side as the wires, and the plug-in devices are on the other side. Because the wires only appear on one side, this type of PCB is called single-sided. Because the single board has many strict restrictions on the design of the circuit, because there is only one side, the wiring cannot cross and must go around a separate path, so only the early circuits used this type of board.

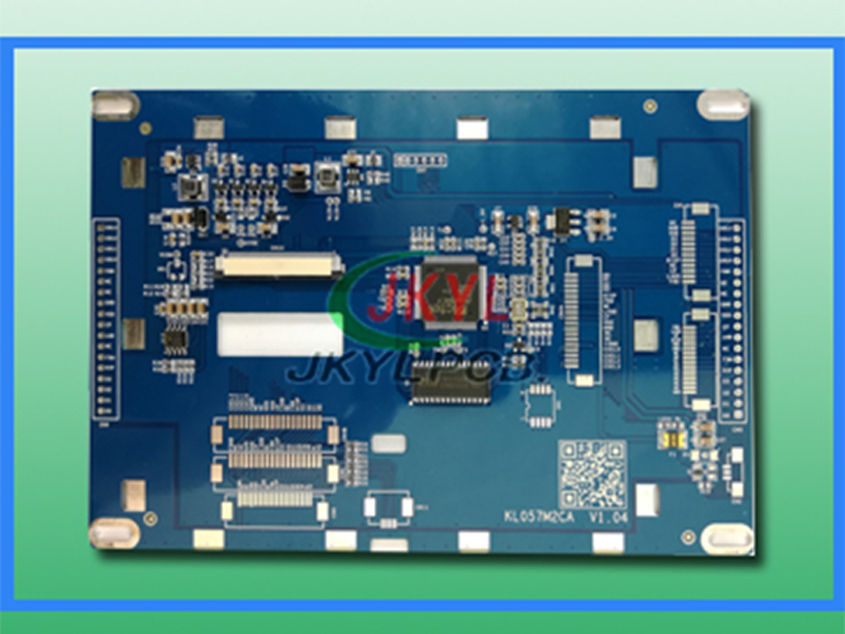

Double panel

The double-sided circuit board has wiring on both sides, but to use the wires on both sides, there must be a proper circuit connection between the two sides. Such "bridges" between circuits are called vias. Vias are small holes on a PCB, filled or painted with metal, that can be connected to wires on both sides. Because the area of the double-sided board is twice as large as that of the single-sided board, the double-sided board solves the difficulty of staggered wiring in the single-sided board. It can be conducted to the other side through the holes, and it is more suitable for use in more complicated circuits than the single-sided board.

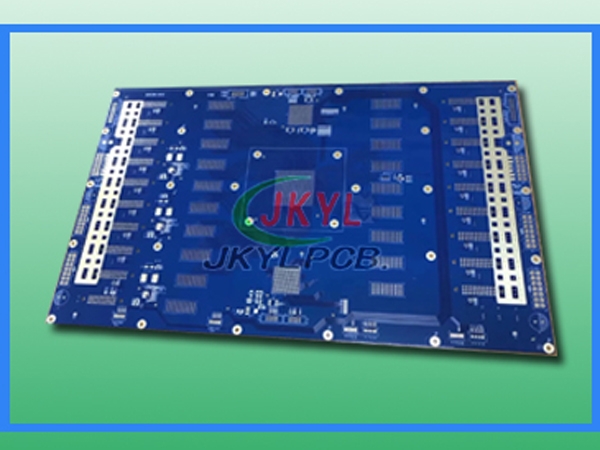

Multilayer board

In order to increase the area that can be wired, multilayer boards use more single or double-sided wiring boards. A printed circuit board with a double-sided inner layer, two single-sided outer layers, or two double-sided inner layers and two single-sided outer layers, alternated together by a positioning system and insulating bonding materials, and conductive patterns. Printed circuit boards that are interconnected according to design requirements become four-layer and six-layer printed circuit boards, also known as multi-layer printed circuit boards. The number of layers of the board does not mean that there are several independent wiring layers. In special cases, an empty layer will be added to control the thickness of the board. Usually, the number of layers is even and includes the outermost two layers. Most motherboards are 4 to 8-layer structures, but technically, nearly 100-layer PCB boards can be achieved. Most large supercomputers use fairly multi-layer motherboards, but because such computers can be replaced by clusters of many ordinary computers, ultra-multi-layer boards have gradually fallen out of use. Because the layers in the PCB are tightly combined, it is generally not easy to see the actual number, but if you look closely at the motherboard, you can still see it.

Features:

The reason why PCB can be used more and more widely is because it has many unique advantages, which are summarized as follows.

High density is possible. For decades, the high density of printed boards has been able to develop with the integration of integrated circuits and the advancement of mounting technology.

High reliability. Through a series of inspections, tests and aging tests, the PCB can be guaranteed to work reliably for a long time (usage period, generally 20 years).

Designability. For various performance requirements of PCB (electrical, physical, chemical, mechanical, etc.), printed board design can be realized through design standardization and standardization, with short time and high efficiency.

producibility. With modern management, standardization, scale (quantification), automation and other production can be carried out to ensure the consistency of product quality.

Testability. A relatively complete test method, test standard, various test equipment and instruments have been established to detect and identify the qualification and service life of PCB products.

Assemblability. PCB products are not only convenient for standardized assembly of various components, but also automated and large-scale mass production. At the same time, PCB and various component assembly parts can also be assembled to form larger parts, systems, and even complete machines.

maintainability. Since PCB products and various component assembly components are standardized in design and mass production, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the service system can be quickly restored. Of course, more examples can be given. Such as the system miniaturization, light weight, high-speed signal transmission and so on.